Lacquers and the Environment

Lacquers and the environment

Typical compositions and properties of the lacquers used in coating tinplate cans have been described elsewhere in this booklet.Since the middle 1970’s the major environmental consideration has been the reduction of the amount of solvents emitted to atmosphere from the coating operation.Typical coatings may have comprised between 40% and 80% solvent, which was emitted to atmosphere from the ovens used to cure the coatings.

These emissions are only a small fraction of total Volatile Organic Compounds (VOC ’s) emitted to atmosphere from all sources, see Table 6, nevertheless, there is an ongoing effort to change the traditional lacquers/coatings, for new technologies with a lower VOC (solvent) content.

Table Typical annual European VOC emissions in early 1990s

|

Typical Annual European VOC Emissions in Early 1990s |

|

|

|

Total VOC Emissions Man-made VOC Emissions Traffic Industrial Solvents/Fuels Traffic Coatings Metal Coatings Can Coatings |

17 million tonnes/year 10 million tonnes/year 3.4 million tonnes/year 1.7 million tonnes/year 1.15 million tonnes/year 0.53 million tonnes/year 0.052 million tonnes/year |

100% 60% 20% 10% 7% 3% 0.3% |

In the presence of Nitrous Oxides (e.g. car emissions) and sunlight, VOC’s can react to form ozone.The generation of ozone at street level in highly populated cities is known as photochemical smog. Ozone is a human poison by inhalation, is irritant to skin, eyes, upper respiratory system and mucous membranes; it has acute effects, e.g. causes coughing, but not chronic (long-term) effects.

For this reason, some cities control the use of cars on the sunniest days of the year. In 1994 and 1995, there were 3,000 instances recorded where ozone levels exceeded 180 µg/m3 (1hr TWA), the level at which the population should be informed. It is calculated that an 80% reduction in NO x and VOC emissions (versus 1990) is necessary to reduce ozone below threshold limit values.National Governments have adopted their own laws to control VOC emissions, e.g. German T.A. Luft regulations (1986) and the U.K. Environmental Protection Act (1991). The E.C . are also drafting European Legislation to control VOC emissions. In the USA, the Environmental Protection Agency and State Legislation force VOC emissions continuously downwards.

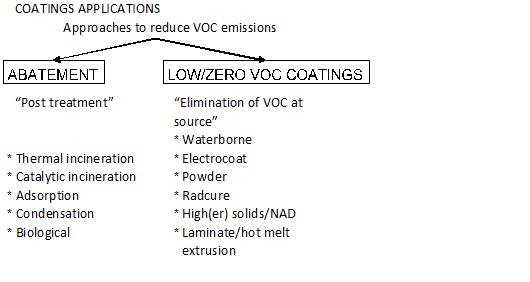

The coatings and lacquer manufacturers have responded to this challenge by developing new coating technologies, which also shows the major methods of VOC abatement, so called “end of pipe” ways of capturing VOC to prevent emission to atmosphere.

- Figure Approaches to reduce VOC emissions

The choice for the canmakers is between abatement and low or zero VOC coatings. Abatement or post treatment is a short-term solution and does not tackle the solvent emission problem at source.The choice of compliant organic coatings is wide and includes waterborne, electrocoat, high solids, powder, radiation curing or lamination/hot melt extrusion.

The choice of organic coatings is wide and each of these has a niche area in our market. Certainly the approach of using low or zero VOC coatings such as UV is far more attractive than expensive abatement. The threatened implementation of a carbon tax will also encourage the use of compliant coatings rather than incinerating expensive solvents.

- Source: The International Tin Association (formerly ITRI Ltd)