Stainless Steel Grade Selection

Stainless Steel Grade Selection

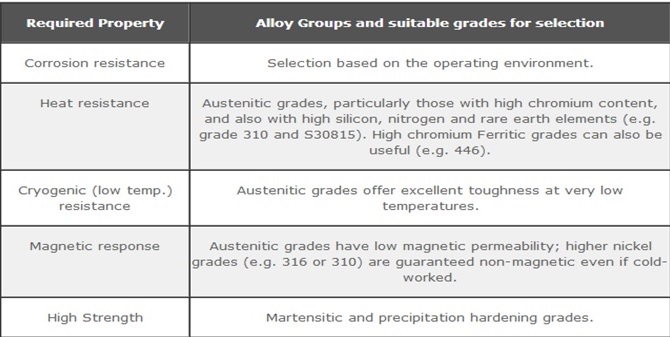

Fundamental Properties for Selection

Selection for corrosion resistance

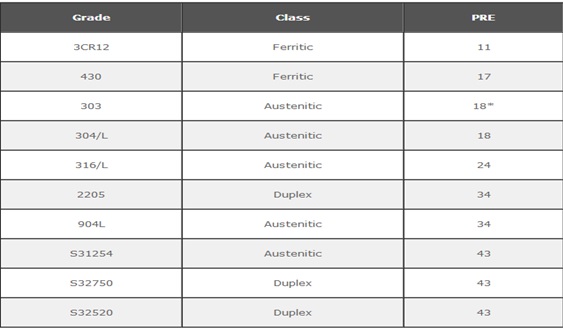

- Stainless steels corrode often through local corrosion. The presence of chloride in the operating environment controls the mechanisms of crevice and pitting corrosion.

- Pitting Resistance Equivalent: The pitting and crevice corrosion resistance of a particular stainless steel grade is denoted by a Pitting Resistance Equivalent number (PRE). PREs can be calculated using the following equation:

PRE = %Cr + 3.3 %Mo + 16 %N

- It was estimated that grades having high alloying elements such as molybdenum, nitrogen and chromium are more resistant to crevice and pitting corrosion. Due to this reason, grade 316, with 2% molybdenum, is used in marine fittings

- The PRE number for various stainless steel grades are tabulated below:

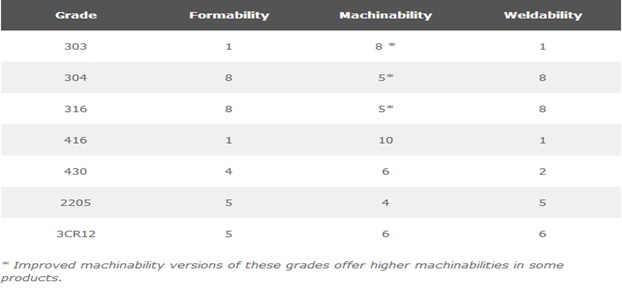

Selection for fabrication

- Grades are selected for corrosion resistance and then consideration is given to how the product can be fabricated.

- Fabrication should be considered as early as possible in the grade selection process, as it greatly influences the economics of the product.

- Fabrication affects the cost-effectiveness of the product; hence this factor must be considered very seriously.

The rate of comparisons in the below table is on arbitrary scales with 10 representing excellent fabrication using a specific method.