Steel Scrap Recycling

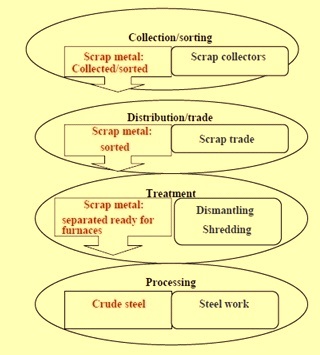

Typical scrap processing cycle:

Collection of steel

- The main place to collect steel is from junkyards or businesses. After collection, the scrap steel is taken in trucks or trains to the processing area where it is to be recycled. The truck with steel is passed through the sensor to check for radiation. Radiation of any kind is considered harmful and that kind of steel is not of any use. After a careful check, the whole lot is transferred to the conveyor belt where it is checked whether the steel is safe for use or not.

Separation and filtering

- The use of the conveyor belt is to convert scrap steel in grinders and cutters. The steel is broken down into small and fine pieces and then sent forward in the process. From the conveyor belt, the steel pieces are moved on to another belt to separate other metals from the steel. In this way, the steel is filtered to remove all kinds of impurities and make it clean.

Pressing

- Pressing means using a baler to press thin sheet steel scrap into bales. The pressed sheet steel scrap might be waste from a punching press or cutter. In the press, the thin, light steel sheet is compressed into cubes. Pressing is also used e.g. to reduce the volume of junk cars (logging). The purpose of pressing is in fact to reduce the volume of the light scrap sheet metal and to increase the volume weight to a weight suitable for the electric steel making. Moreover, pressing can also reduce transport costs and facilitate storage. Pressing can also include briquetting, i.e. pressing lathe chips into briquettes.

Crushing

- Crushing is done with various metal crushers. Crushing is used in the processing of thin or dirty sheet steel scrap and junk cars. The purpose of crushing is to break down the steel scrap metal into smaller pieces so that the different metals can be separated and the impurities removed. For example, crushing cars produces clean, palm-sized, rust-free clumps that can be picked off later with a magnet. In this phase, also the plastics, wood, rubber, sand and other impurities are crushed so small that they can be removed.

Shearing

- Shearing means the cutting and pressing of thicker scrap steel. Shearing takes place in big, guillotine-like scrap shears. Steel beams and miscellaneous scrap are cut into – 60cm or – 80 cm pieces. Shearing increases the bulk density of the scrap, making it easier to handle and portion out.

Shredding

- Shredders incorporate rotating magnetic drums to extract iron and steel from the mixture of metals and other materials.

Sorting

- Sorting is the process of separating the different metals and other materials. This is done using magnets, eddy current separators, screening, blowing/suction (air classifier), flotation (gravitational separation), optical separation and manual separation.

Schematics of typical scrap processing cycle is