Steel Substrates for Galvanizing

Steel Substrates for Galvanizing

Steels for continuous galvanizing can be categorized into the following major groups

Commercial Steel (CS) – carbon levels range between 0.04% and 0.10%, and manganese from 0.2% to 0.6%, depending on the product being made. The substrate is cold rolled anywhere from 50 to 80% reduction prior to it being processing through a galvanize line.

Forming Steel (FS) – carbon levels between 0.04-0.08%, and manganese at about 0.25%. This steel is cold reduced between 60 to 80% and is used to produce a slightly softer product than CS in order to give improved formability.

Structural Steel (SS) – carbon levels range between 0.04% and 0.20%, and manganese from 0.4% to 1.6%, depending on the product being made. The sheet is cold rolled anywhere from 50 to 70% reduction. SS grades must meet minimum mechanical property requirements and have yield strengths between 33 and 80 ksi [230 and 550 MPa].

Deep Drawing Steel (DDS) & Extra Deep Drawing Steel (EDDS) – generally made from ultra-low carbon (10-15 ppm) stabilized steels, although some DDS is made using extra low carbon (0.0150.020%) steel. EDDS, and some DDS, is fully stabilized (non-ageing) after in-line annealing and coating. To maximize annealing response, cold reduction is generally 75% minimum.

Solution Hardened Steel (SHS) & Bake Hardenable Steel (BHS) – ultra-low to low carbon (0.12% max) steel that has yield strengths from 26 to 44 ksi [180 to 300 MPa]. SHS is strengthened using substitutional elements such as M, P, or Si, while BHS relies on strain ageing after forming for strengthening.

High Strength-Low Alloy Steel (HSLAS) – typically made from micro-alloyed low carbon steel. The primary micro-alloying element is niobium (Nb). Cold reduction rarely exceeds 60% due to the high cold rolling loads necessary to reduce the thickness of these steels. They have yield strengths of 40 to 80 ksi [275 to 550 MPa].

Advanced High Strength-Low Alloy Steel (AHSS) – Produced using higher levels of alloying elements, including manganese, silicon, aluminum, and carefully controlled annealing and cooling cycles. Cold reduction rarely exceeds 60% due to high cold rolling loads. The yield strength of these steels is typically between 50 and 80 ksi [340 and 545 MPa].

Effects of Alloying Addition on Steel Properties

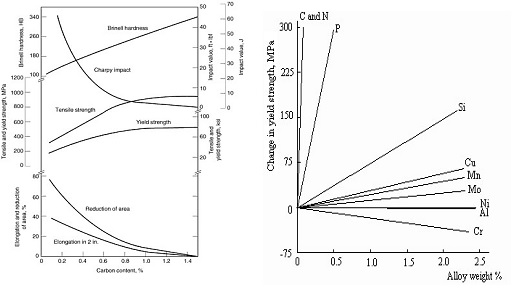

- Carbon – Is the most important steel alloying element, having the greatest effect on steel properties. Carbon is part of integrated steelmaking operations starting with the blast furnace.

- Manganese – Was initially used to control “hot shortness”, a problem associated with sulfur in steel. Now it is used for strengthening and is intentionally added.

- Sulfur – Undesirable in almost all steels. Comes from the sulfur in coal or the ore. In most cases processing practices are in place to minimize the sulfur content.

- Phosphorus – Often present at very low levels, residual amounts – less than 0.01%. Can be added to increase strength.

- Silicon – Usually present only as a residual element, typically less than 0.01%. Can be added as a strengthener to produce high strength steels. May cause problems during hot-dip coating, as it is difficult to “reduce” silicon oxides in continuous annealing furnaces.

- Aluminum – Added to “kill” the steel during casting, i.e., prevent oxygen out-gassing problems during solidification. Also, can tie up the nitrogen to minimize “aging”. Used to make deep-drawing steels.

- Nitrogen – Present as an impurity; coming from handling molten steel in air. Sometimes intentionally added if higher strength needed.

- Niobium, Titanium & Vanadium – Intentionally added to strengthen steels. Nb and Ti are also used as stabilizers in IF steels.

- Copper, Nickel & Chromium – Typically present only as impurities. When added, are used for hardening and/or strengthening.

Figure 1 Effect of C on mechanical properties, (a); effect of alloying elements on yield strength, (b)

Ultra Low Carbon Stabilized Steel

Carbon (C) and nitrogen (N) in sheet steel results in higher mechanical properties, age hardening, and deterioration of the r-value (measure of resistance to thinning and drawability).

Liquid steel is processed through a degasser to reduce C and N to levels low enough that the remainder can be “stabilized” by small additions of titanium (Ti) and niobium (Nb).

Ti and Nb are strong carbide/nitride formers, taking the remaining C and N out of solution in liquid iron, after which these latter two elements are no longer available to reside in the interstices between solidified iron atoms.

The term “Interstitial-Free” or “IF” steel refers to the fact that there are no interstitial solute atoms to strain the solid iron lattice, resulting in very soft steel.

Non-ageing IF steel has no yield point elongation, which means fluting and stretcher strains are never a problem.

IF steel made using only Ti is very common and is used to produce the best mechanical properties for deep drawing. It is very reactive in a zinc bath and is usually coated only as galvanize (GI).

Another popular type of IF steel is stabilized with both Ti and Nb. The synergy of these two elements allows complete stabilization to be achieved at lower levels of each element. Depending on the relative amounts of Ti and Nb, the steel needs to be annealed at a higher temperature during galvanizing and has slightly inferior mechanical properties to the Ti type. Ti-Nb type IF is also less reactive in a zinc bath and is usually employed when producing galvanneal (GA).

IF steels are ideal for directly producing DDS and EDDS hot-dip products by the continuous anneal process. During the zinc coating and galvannealing steps the strip is reheated above the overageing temperature. If low carbon steel were being used, carbon would redissolve, and could cause strain ageing. With IF steels, cooling and reheating is irrelevant, since carbon (and nitrogen if present) are not available to be redissolved and cause aging.

One type of EDDS made using stabilized steel is actually a higher strength steel with a minimum yield strength of 30 ksi [205 MPa]. Made using phosphorous additions of up to 0.06%, it combines good formability with high strength, producing better dent resistance on exterior panels

Stabilized, ultra low carbon (ULC), interstitial-free steel has the ability, during continuous annealing, to form crystal orientations favorable to deep drawing. This is not possible with low carbon, unstabilized steel on continuous annealing lines. The high r-values needed for good steel drawability require plentiful “cube-on-corner” crystal orientations to form during annealing. This becomes increasingly possible when the carbon level is below 0.01%, and is optimized at 0.001% (10 ppm).

Most formable steels (whether IF or carbon) have manganese levels below 0.20%, and the formability improves as the carbon level is lowered. Manganese becomes more damaging to r-values as the carbon level increases. R-value is maximized when ULC steel with 10-ppm carbon and about 0.15% Mn is completely stabilized using Ti.

Some advantages of ULC stabilized steel are: superior stamping, forming, and drawing performance; the ability to make more complex parts, perhaps using a fewer numbers of dies; age hardening resistance (long shelf life for stored steel); and improved coating adhesion for galvanized products.

The main disadvantage of ULC stabilized steel is that it can be very soft, resulting in shearing and punching difficulties, and its use may result in parts that are not as ‘strong’, i.e., dent resistant, compared to parts made from carbon steel.

Bake Hardenable Steel

Using ultra-low-carbon vacuum-degassed steel, and precise alloying additions, partially stabilized steel can be produced that has a low amount of solute carbon available after precipitation reactions are completed on the galvanizing line.

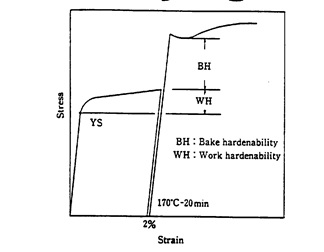

Bake hardenable steel (BHS) takes advantage of the low solute carbon to produce controlled carbon strain aging to augment the yield strength of formed automotive panels, thus improving dent resistance or permitting some thickness reduction. The strain comes from press forming and aging is accelerated by the paint baking treatment. BH steels contain enough supersaturated solute carbon that the aging reaction typically adds 4 to 8 ksi [27 to 55 MPa] to stamped panel yield strength.

This approach to providing higher strength panels has the advantage of presenting formable low yield strength material to stamping operations so as to avoid panel shape problems due to elastic deflection associated with initial yield strengths exceeding 35 ksi [240 MPa]. BHS is the practical consequence of modern manufacturing technologies, which permit control of supersaturated solute carbon at a level that is just high enough to provide a useful amount of accelerated strain aging, without aging during transport/storage. The BHS process produces a coated product that will be free from stretcher strains for at least 2 to 3 months after its production, allowing stampers time to consume it before its mechanical properties begin to deteriorate due to aging.

Figure 2 illustrates the concept of bake hardening, with BH representing the flow stress increase on baking. This chart also represents the typical strain and baking conditions for the least formed areas of automotive panels.

Figure 2 Bake hardening phenomenon

It can be seen that when producing BHS on a hot-dip CGL the most critical parts of the process involve trapping solute carbon by fast cooling through the carbide precipitation range, and avoiding cementite precipitation by quickly passing through the overaging zone to the zinc bath entry temperature.

What is Strain Aging?

A sudden, sharp transition from elastic to plastic deformation when low carbon steel is stressed in tension is called the yield point. The mechanism by which steel yields is the movement of crystal lattice imperfections called dislocations. Solute carbon and nitrogen atoms in steel anchor dislocations, to which they diffuse because that lowers overall crystal strain energy. When stressed sufficiently, the dislocations are suddenly freed from their local atmospheres of interstitial carbon and nitrogen atoms, resulting in a sharp yield point. This yield point can be suppressed by straining the steel, e.g., by leveling, stamping, etc., which introduces “tangles” of unpinned dislocations away from carbon and nitrogen atmospheres. The result is a smooth transition from elastic to plastic deformation, i.e., a rounded stress strain curve because the dislocations can now move incrementally. Strain aging is the later reappearance of the yield point at a higher stress. It happens as time passes (aging) due to the diffusion of carbon and nitrogen atoms to form new interstitial atmospheres at dislocations, anchoring them once more. Elevated temperature accelerates the movement of carbon and nitrogen to dislocations. In the case of bake hardenable steels, stamping introduces the strain, and paint baking accelerates aging, the end result of which is stronger, more dent resistant auto body panels – an example of using a normally unwanted steel property to good advantage.

What is High Strength Steel?

There are various approaches to making high strength steels. For many years galvanize with 80 ksi yield strength has been produced using a “full hard” (unannealed or recovery annealed) method (ASTM A653/A653M, Grade 80 [550 MPa]). This product is strong but has very limited ductility. It is typically used for such products as roll-formed building siding.

High strength steel sheet can be produced using solid solution strengthening or precipitation hardening.

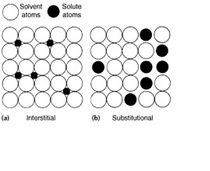

Solid solution hardening is used mostly for high strength structural steels and is accomplished by using alloy additions (solute) that are interstitial and/or substitutional in the solvent metal as illustrated in Figure 3. It achieves high strength with moderate formability. The interstitial approach uses elements such as carbon and nitrogen that stretch the ferrite lattice. This mechanism is usually combined with substitutional elements such as manganese, silicon, and phosphorous, which replace iron, also stretching the ferrite lattice.

Figure 3 Interstitial (a) and substitutional (b) solution strengthening

The above 2 mechanisms are used to produce galvanized steels with yield strengths up to about 65 ksi [450 MPa] with reasonable formability. Steels of this type have a characteristic low (<0.75) yield/tensile (Y/T) ratio and are mostly used for structural applications.

Precipitation hardening and grain refinement is used in the production of high strength-low alloys steel, using alloying elements, such as V, Nb, and Ti, to combine with C and/or N to form very small carbide/nitride precipitates. These steels are more formable than structural high strength steel and have a high (>0.80) Y/T ratio.

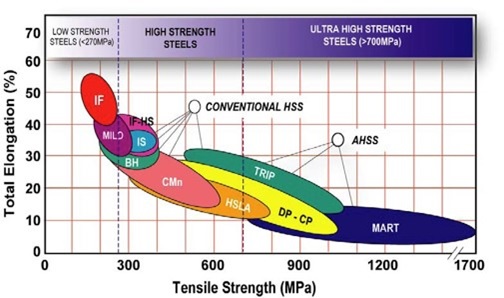

Advanced high strength steels (AHSS) are a relatively new class of high strength steels produced using higher alloy levels combined with special in-line thermal treatment. They combine very high strength with good ductility and have lower Y/T ratios than HSLAS.

What is High Strength-Low Alloy Steel (HSLAS) ?

High strength-low alloy galvanize is produced using precipitation hardening reactions during annealing and uses alloying elements, such as Nb, and Ti, to combine with C and/or N to form very small carbide/nitride precipitates. Hardening results from the precipitates preventing or altering dislocation (lattice defect) movement in the steel. Precipitates also act as grain refiners by pinning the recrystalization interfaces. Also, recrystalization is delayed until the carbides grow in size, resulting in much smaller grain size. Yield strength increases since it is inversely proportional to ferrite grain size. Niobium at a level as low as 0.005% is effective because of its high atomic weight, and NbC precipitates do not dissolve at continuous annealing temperatures, making them available for both precipitation hardening and grain refinement. These techniques are used to produce HSLAS with yield strengths from 40 to 60 ksi [275 to 410 MPa].

Vanadium is not used as microalloying element for galvanize because VN precipitates dissolve at the continuous annealing temperatures used, the N combines with Al, and the precipitates are lost.

Figure 4 shows a drawing of the nature of HSLAS microstructure.

Figure 4 Microstructure of HSLA steel

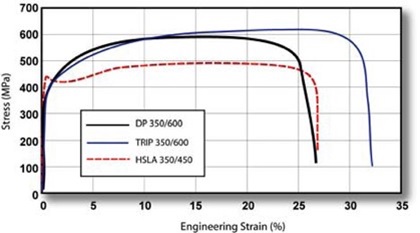

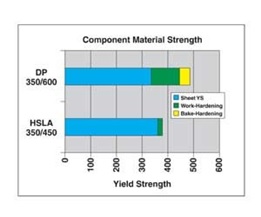

The typical HSLA stress-strain curve (lower curve in Figure 5) has very little difference between the yield point and the ultimate tensile strength (a high Y/T ratio, ~0.80-0.84). It is moderately formable but will fracture at stresses close to its yield point. This is the primary reason behind HSLAS losing favour for automotive applications, i.e., it cannot match the performance of the higher strength, more formable grades in the AHSS family.

What is Advanced High Strength Steel (AHHS)?

As automobile companies are committed to lowering the CO2 emissions of their products, and weight reduction is an integral part of achieving this, AHSS technology offers an excellent means of contributing to this goal. Another important requirement for vehicles is to perform well in collisions. This requires steels with tensile strengths as high as are compatible with the demanding formability requirements required by the fabrication processes. Some AHSS grades with about 50 ksi [340 MPa] YS, and about 85 ksi [600 MPa] tensile strength (TS) are still used but are almost phased out. Development has proceeded actively in Europe, Japan and America over the last two decades and includes Dual Phase (DP), Multi Phase (MP) or Complex Phase (CP), and Transformation Induced Plasticity (TRIP) steels.

Current production is mostly Dual Phase (DP). Active development of Transformation Induced Plasticity (TRIP) coated sheet is underway. Typical alloying strategies involve the use of elements such as C, Si, Mn, P, Cr, Mo, and Al. Rapid cooling and isothermal holding are required during continuous annealing to achieve the required mechanical properties. The main goal is better formability at a given strength level and, in some cases, post forming strengthening. Figure 5 illustrates the tensile properties of these steels compared the HSLAS.

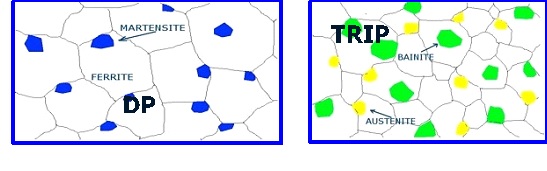

The microstructure of DP and TRIP steels are shown in Figure 6. It is the very hard martensite and bainite constituents in the soft ferrite matrix that give these steels their combination of high strength and good ductility. TRIP steels also have untransformed austenite when they are made, which then transforms to harder constituents as a result of the energy input from forming operations. This “delayed reaction” produces stronger finished parts, allowing further reduction in steel thickness.

Figure 6 Microstructure of Dual Phase (a) and TRIP (b) steels

DP and TRIP steels have much lower Y/T ratios (~0.60) compared to HSLAS as shown in the upper two stress-strain curves in Figure 5. After yielding, they have the capacity to absorb considerably more deformation before fracturing. Consequently, the finished part ends up with a much higher strength than if made with HSLA. This allows a thinner steel to be used to produce a part of equivalent strength.

TRIP steels (top curve in Figure 5) have a similar Y/T ratio to DP steels, but are stronger, and can work harden more, with equivalent or better formability. The low Y/T ratio that is characteristic of DP and TRIP steels is being used to advantage in more than one way by automotive designers. Not only is there the benefit of weight savings, but these steels also provide gains in crash energy management, resulting in safer vehicles. The larger capacity for work hardening absorbs more energy during a crash, energy that is not transferred to the vehicle occupants.

DP and TRIP steels have much lower Y/T ratios (~0.60) compared to HSLAS as shown in the upper two stress-strain curves in Figure 5. After yielding, they have the capacity to absorb considerably more deformation before fracturing. Consequently, the finished part ends up with a much higher strength than if made with HSLA. This allows a thinner steel to be used to produce a part of equivalent strength.

TRIP steels (top curve in Figure 5) have a similar Y/T ratio to DP steels, but are stronger, and can work harden more, with equivalent or better formability. The low Y/T ratio that is characteristic of DP and TRIP steels is being used to advantage in more than one way by automotive designers. Not only is there the benefit of weight savings, but these steels also provide gains in crash energy management, resulting in safer vehicles. The larger capacity for work hardening absorbs more energy during a crash, energy that is not transferred to the vehicle occupants.

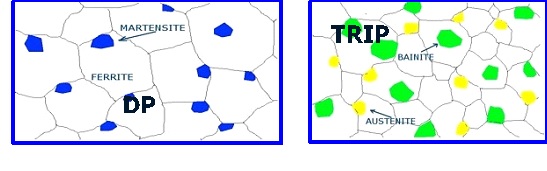

Figure 7 illustrates the benefit of using Dual Phase steel over HSLA in the manufacture of structural parts. The lower Y/T ratio of the DP allows a much higher work hardening component to add to the strength of the part. An added benefit is that DP steel also has a bake-hardening component that adds strength after the part is heated to paint baking temperatures.

Summary

The relationship of tensile strength to ductility of the family of steels used for coated sheet (except martensitic – MART – steel) is illustrated in Figure 8, also known as the “banana” curve. It is evident that the advantages of AHSS are only beginning to be tapped, since there are few developed grades with TS greater than 900 MPa.

- Source: www.galvainfo.com