About Prepainted Metal

What is prepainted Metal?

Prepainted metal is a high quality product manufactured under strict quality control in the coil coating process. The main substrates for prepainted metal are steel and aluminium strip and these are usually coated with a liquid paint by rollercoating, although sometimes a preformed film is laminated to the surface and occasionally a powder-paint is applied in coil coating.

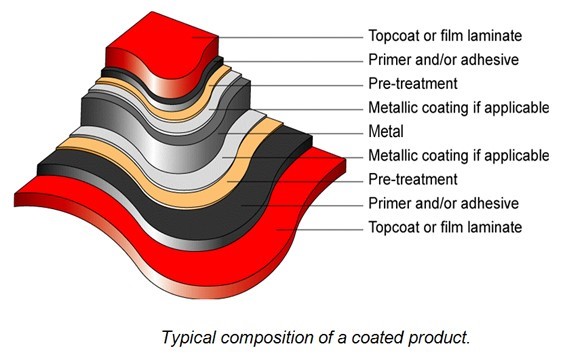

A prepainted metal product is a synergistic combination of the metal substrate, any metallic coating which may be used, an efficient cleaning and chemical conversion process and usually 2, but up to 4 different paint coatings. The coil coating process allows different coatings to be used on the two sides of the metal strip, so the possibilities are endless.

Each producer of prepainted metal offers their own, sometimes branded, selection of prepainted metal products. It is beyond the scope of ecca to compare all of these products, but this ecca Technical Paper attempts to provide a guide to the main product types, together with their main uses, advantages and disadvantages.

Prepainted Metal as a System

In terms of the quality of prepainted metal, two main factors set this apart from traditional paint coatings on metal:

- The uniformity of cleaning, pretreatment and coating afforded by the highly controlled coil coating process;

- The synergistic nature of the different layers that make up a prepainted metal product and which are well thought-out to work together. A prepainted metal product is a combination of several layers, as depicted in Figure below

It is the combination of these layers which provides the final properties of the prepainted metal product, but some show more variation than others. Prepainted metal products are generally referred to by their topcoat and while the focus of this paper is mainly on the varieties of topcoat, it is important to remember that the other layers will also play a part.

The choice of metal substrate and, to a lesser extent, any metallic coating, is generally one for the customer, but usually the pre-treatment and primer will be selected by the coil coater to be the most appropriate for a given combination of topcoat and substrate. Very often, the topcoat is only specified on one side, with the back-side having a simple, low-cost topcoat.

However, the back-side topcoat can also be selected, depending on the requirements in the end use, to give improved appearance, improved performance, additional functionality or reduced cost.

Thickness of coatings is usually quoted for the combination of top-coat and primer. In the majority of cases, the primer is a thin layer, of the order of 4 µm, the majority of the coating being the top-coat. However, there are cases where a much thicker primer can be used, such as the high-build polyurethanes, where the primer can be up to half of the overall thickness. For multi-coat systems, such as 3- or 4-coat PVDF, the total thickness including primer and 2 or 3 top-coats is usually quoted, the thickness of each layer being required for it’s individual function in the total system.

There are three main categories of topcoat:

- Liquid paint

- Film

- Powder paint

Over 90% of prepainted metal uses liquid paint, so a fuller description is given here of what makes up a liquid paint and what differentiates one paint from another. Films and Powder paints are covered later in this paper.

- Source: http://www.prepaintedmetal.eu