Die Casting

INTRODUCTION

Cold Chamber Process

Hot Chamber Process

Die cast parts are used for many industries including pumps and valves, propane gas, automotive, aerospace, business and office, construction and medical.

Types of Die Casting

1. Gravity Casting

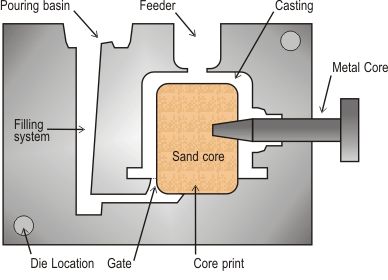

- Schematic view in below Figure shows the main parts constituting a classical mould for gravity die casting. Cores (inner parts of the mould) are generally made of bonded sand.

2. High Pressure Die Casting

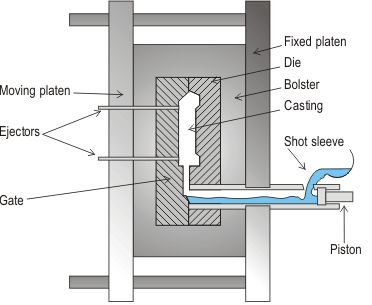

- In this process, the liquid metal is injected at high speed and high pressure into a metal mould. A schematic view of high pressure die casting is given in below Figure.

- This equipment consists of two vertical platens on which bolsters are located which hold the die halves. One platen is fixed and the other can move so that the die can be opened and closed. A measured amount of metal is poured into the shot sleeve and then introduced into the mould cavity using a hydraulically-driven piston. Once the metal has solidified, the die is opened and the casting removed.

- In this process, special precautions must be taken to avoid too many gas inclusions which cause blistering during subsequent heat-treatment or welding of the casting product.

- Both the machine and its dies are very expensive, and for this reason pressure die casting is economical only for high-volume production.

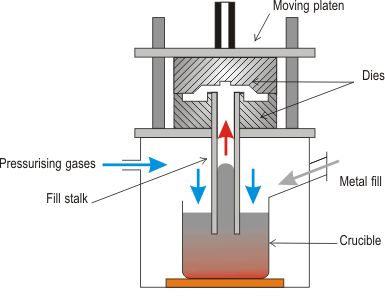

3. Low Pressure Die Casting

- As schematised in below Figure, the die is filled from a pressurised crucible below, and pressures of up to 0.7 bar are usual. Low-pressure die casting is especially suited to the production of components that are symmetric about an axis of rotation. Light automotive wheels are normally manufactured by this technique.

4. Vacuum Die Casting

- As schematised in below Figure, the die is filled from a pressurised crucible below, and pressures of up to 0.7 bar are usual. Low-pressure die casting is especially suited to the production of components that are symmetric about an axis of rotation. Light automotive wheels are normally manufactured by this technique.

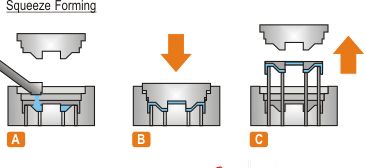

5. Squeeze Casting or Squeeze Forming

- As shown in below Figure, liquid metal is introduced into an open die, just as in a closed die forging process. The molten metal is poured into the bottom half of the pre-heated die. As the metal starts solidifying, the upper half closes the die and applies pressure during the solidification process. The amount of pressure thus applied is significantly less than used in forging, and parts of great detail can be produced. Coring can be used with this process to form holes and recesses. The porosity is low and the mechanical properties are improved.. During the final stages of closure, the liquid is displaced into the further parts of the die. No great fluidity requirements are demanded of the liquid, since the displacements are small. Thus forging alloys, which generally have poor fluidities which normally precludes the casting route, can be cast by this process.

- Squeeze casting, also known as liquid metal forging, is a combination of casting and forging process. This process aims to improve product quality by solidifying the casting under a metallostatic pressure head sufficient to (a) prevent the formation of shrinkage defects and (b) retain dissolved gases in solution until freezing is complete. It is carded out in metal molds resembling, the punch and die sets used in sheet metal forming

- Both ferrous and non-ferrous materials can be produced using this method. It produces very low gas entrapment and castings exhibit shrinkage volumes approximately one half those seen in sand castings. Very high production rates, comparable to die casting but with considerably lower die costs, are also possible. The process produces the high quality surfaces typical of metal mold casting, with good reproduction of detail. Rapid solidification results in a fine grain size, which improves mechanical properties. It is claimed that squeeze casting can be applied to many of the copper alloys, although die and permanent mold casting alloys should be favored

- This technique is especially suited for making fibre-reinforced castings from fibre cake preform. Squeeze casting forces liquid aluminium to infiltrate the preform. In comparison with non-reinforced aluminium alloy, aluminium alloy matrix composites manufactured by this technique can double the fatigue strength at 300°C. Hence, such reinforcements are commonly used at the edges of the piston head of a diesel engine where solicitations are particularly high.

Common Alloys in Die Casting

- Aluminum, Zinc and Copper alloys are the materials predominantly used in die-casting. On the other hand, pure Aluminum is rarely cast due to high shrinkage, and susceptibility to hot cracking. It is alloyed with Silicon, which increases melt fluidity, reduces machinability. Copper is another alloying element, which increases hardness, reduces ductility, and reduces corrosion resistance.

- Aluminum is cast at a temperature of 650 ºC (1200 ºF). It is alloyed with Silicon 9% and Copper about 3.5% to form the Aluminum Association 380 alloy (UNS A03800). Silicon increases the melt fluidity, reduces machinability, Copper increases hardness and reduces the ductility. By greatly reducing the amount of Copper (less than 0.6%) the chemical resistance is improved; thus, AA 360 (UNS A03600) is formulated for use in marine environments. A high silicon alloy is used in automotive engines for cylinder castings, AA 390 (UNS A03900) with 17% Silicon for high wear resistance. Common aluminum alloys for die casting are summarized as follows:

Material | Silicon | Copper | Tensile Strength MPa (Ksi) | Properties |

AA 380 | 8.5 % | 3.5 % | 324 | Fair easy to fill |

AA 384 | 11 % | 4 % | 331 | Easy to fill |

AA 386 | 9.5 % | 0.6 % | 317 | Good corrosion resistance |

AA 390 | 17% | 4.5 % | 283 | Good wear resistance |

- Zinc can be made to close tolerances and with thinner walls than Aluminum, due to its high melt fluidity. Zinc is alloyed with Aluminum (4%), which adds strength and hardness. The casting is done at a fairly low temperature of 425 ºC (800 ºF) so the part does not have to cool much before it can be ejected from the die. This, in combination with the fact that Zinc can be run using a hot chamber process allows for a fast fill, fast cooling (and ejection) and a short cycle time. Zinc alloys are used in making precision parts such as sprockets, gears, and connector housings.

- Copper alloys are used in plumbing, electrical and marine applications where corrosion and wear resistance is important.

- Minimum wall thicknesses and minimum draft angles for die casting are:

Material | Min. Thickness mm (in) | Min. Draft Angle (° ) |

Aluminium Alloys | 0.9 mm | 0.5 |

Zinc alloys | 0.6 mm | 0.25 |

Copper alloys (Brass) | 1.25 mm | 0.7 |

- Die-castings are typically limited from 20 kg (55 lb) max. for Magnesium, to 35 kg (77 lb) max. for Zinc. Large castings tend to have greater porosity problems, due to entrapped air, and the melt solidifying before it gets to the furthest extremities of the die-cast cavity. The porosity problem can be somewhat overcome by vacuum die casting

- From a design point of view, it is best to design parts with uniform wall thicknesses and cores of simple shapes. Heavy sections cause cooling problems, trapped gases causing porosity. All corners should be radiused generously to avoid stress concentration. Draft allowance should be provided to all for releasing the parts-these are typically 0.25º to 0.75º per side depending on the material.

Advantages of Die Casting

- The Die Casting manufacturing process offers many advantages and benefits.

1. Die casting provides complex shapes within closer tolerances than many other mass production processes.

2. Die castings are produced at high rates of production. Little or no machining is required.

3. Die castings can be produced with thinner walls than those obtainable by other casting methods … and much stronger than plastic injection moldings with the same dimensions.

4. Die casting provide parts which are durable, dimensionally stable, and have the feel and appearance of quality.

5. Die casting dies can produce thousands of identical castings within specified tolerances before additional tooling may be required.

6. Zinc castings can be easily plated or finished with a minimum of surface preparation.

7. Die castings can be produced with surfaces simulating a wide variety of textures.

8. Die cast surfaces, as cast, are smoother than most other forms of casting.

9. Holes in die casting can be cored, and made to tap drill sizes.

10. External threads on parts can be readily die cast.

11. Die castings provide integral fastening elements, such as bosses and studs, which can result in assembly economies.

12. Inserts of other metals and some non-metals can be die cast in place.

13. Corrosion resistance of die casting alloys rates from good to high.

14. Die castings are monolithic. They combine many functions in one, complex shaped part. Because die castings do not consist of separate parts, welded or fastened together, the strength is that of the material, not that of threads or welds, etc.

15. Die casting is an efficient and economical alternative to other processes. When used to its maximum potential it can replace assemblies of a variety of parts produced by various manufacturing processes at significant savings in cost and labor.

Die Casting vs. Other Processes

Die Casting vs. Plastic Molding – Die casting produces stronger parts with closer tolerances that have greater stability and durability. Die cast parts have greater resistance to temperature extremes and superior electrical properties.

Die Casting vs. Sand Casting – Die casting produces parts with thinner walls, closer dimensional limits and smoother surfaces. Production is faster and labor costs per casting are lower. Finishing costs are also less.

Die Casting vs. Permanent Mold – Die casting offers the same advantages versus permanent molding as it does compared with sand casting.

Die Casting vs. Forging – Die casting produces more complex shapes with closer tolerances, thinner walls and lower finishing costs. Cast coring holes are not available with forging.

Die Casting vs. Stamping – Die casting produces complex shapes with variations possible in section thickness. One casting may replace several stampings, resulting in reduced assembly time.

Die Casting vs. Screw Machine Products – Die casting produces shapes that are difficult or impossible from bar or tubular stock, while maintaining tolerances without tooling adjustments. Die casting requires fewer operations and reduces waste and scrap.

GLOSSARY DIE CASTING

Automation – Industry term commonly used to describe the mechanization of various aspects of the die casting process.

Biscuit – Excess of ladled metal remaining in the shot sleeve of a cold chamber die casting machine. It is part of the cast shot and is removed from the die with the casting.

Blister – A surface bubble caused by gas expansion (usually from heating) which was trapped within the die casting or beneath the plating.

Blow holes – Voids or pores which may occur due to entrapped gas or shrinkage during solidification, usually evident in heavy sections (see porosity).

Cavity – The recess or impressions in a die in which the casting is formed.

Cold chamber machine – A type of casting machine in which the metal injection mechanism is not submerged in molten metal.

Checking – Fine cracks on the surface of a die which produce corresponding raised veins on die castings. Caused by repeated heating of the die surface by injected molten alloys.

Creep – Plastic deformation of metals held for long periods at stresses lower than yield strength.

Die lubricant – Liquid formulations applied to the die to facilitate casting release and prevent soldering.

Dimensional stability – Ability of a component to retain its shape and size over a long period in service.

Dowel pin – A guide pin which assures registry between cavities in two die halves.

Draft – The taper given to walls, cores and other parts of the die cavity to permit easy ejection of the casting.

Ejector marks – Marks left on castings by ejector pins.

Ejector plate – A plate to which ejector pins are attached and which actuates them.

Fillet – Curved junction of two surfaces, e.g., walls which would meet at a sharp angle.

Flash – A thin web or fin of metal on a casting which occurs at die partings, vents and around moveable cores. This excess metal is due to working and operating clearances in a die.

Gate – Passage for molten metal which connects runner with die cavity. Also, the entire ejected content of a die, including castings, gates, runners, sprue (or biscuit) and flash.

Gooseneck – Spout connecting a metal pot or chamber with a nozzle or sprue hole in the die and containing a passage through which molten metal is forced on its way to the die. It is the metal injection mechanism in a hot chamber type of die casting machine.

Growth – Expansion of a casting as a result of aging or of intergranular corrosion, or both.

Heat checking – (See checking)

Hot chamber machines – Die casting machines which have the plunger, gooseneck (metal pressure chamber) immersed in molten metal in the holding furnace.

Hot short – Term used to describe an alloy which is brittle or lacks strength at elevated temperatures.

Impact strength – Ability to resist shock, as measured by a suitable testing machine.

Impression – Cavity in a die. Also, the mark or recess left by a ball, or penetrator of a hardness tester.

Ingot – Metal or alloy cast in a convenient shape for storage, shipping and remelting.

Injection – The process of forcing molten metal into a die.

Insert – A piece of material, usually metal, which is placed in a die before each shot. When molten metal is cast around it, it becomes an integral part of the die casting.

Intergranular corrosion – A type of corrosion which preferentially attacks grain boundaries of metals or alloys, resulting in deep penetration.

Loose piece, knockout – A type of core (which forms undercuts) which is positioned in, but not fastened to a die. It is so arranged as to be ejected with the casting and from which it is removed. It is used repeatedly for the same purpose.

Metal saver – Core used primarily to reduce amount of metal in a casting and to avoid sections of excessive thickness.

Multiple cavity die – A die having more than one duplicate impression.

Nozzle – Outlet end of a gooseneck or the tubular fitting which joins the gooseneck to the sprue hole.

Overflow-well – A recess in a die connected to a die cavity by a gate to assist in proper venting.

Parting line – A mark left on a die casting where the die halves meet; also, the mating surface of the cover and ejector portions of the die.

Plunger – Ram or piston which forces molten metal into a die.

Port – Opening through which molten metal enters the injection cylinder.

Porosity – Voids or pores resulting from trapped gas, or shrinkage during solidification.

Process control – Where parameters of a process are studied and correctly applied in the manufacturing process to produce high quality parts.

Runner – Die passage connecting sprue or plunger holes of a die to the gate where molten metal enters the cavity or cavities.

Shot – That segment of the casting cycle in which molten metal is forced into the die.

Shrinkage, solidification – Dimensional reduction that accompanies the freezing (solidification) of metal passing from the molten to the solid state.

Shrink mark – A surface depression which sometimes occurs next to a heavy section that cools more slowly than adjacent areas.

Slide – The portion of the die arranged to move parallel to die parting. The inner end forms a part of the die cavity wall that involves one or more undercuts and sometimes includes a core or cores.

Soldering – Adherence of molten metal to portions of the die.

Split gate – A gate of castings having the sprue or plunger axis in the die parting.

Sprue – Metal that fills the conical passage (sprue hole) which connects the nozzle with runners.

Sprue pin – A tapered pin with rounded end projecting into a sprue hole and acting as a core which deflects metal and aids in the removal of the sprue.

Toggle – Linkage employed to mechanically multiply pressure when locking the dies of a casting machine.

Trim die – A die for shearing or shaving flash from a die casting.

Unit die – A die interchangeable with others in a common holder.

Undercut – Recess in the side wall or cored hole of a casting disposed so that a slide or special form of core (such as a knockout) is required to permit ejection of the casting from the die.

Vent – Narrow passage at the die parting which permits air to escape from the die cavity as it is filled with molten metal.

Void – A large pore or hole within the wall of a casting usually caused by entrapped gas. A blow hole.

Waterline – A tube or passage through which water is circulated to cool a casting die.