Types of CRGO

Types of CRGO - Cold Rolled Grain Oriented Electrical Steel

Grain oriented electrical steel is an important material in the production of energy efficient transformers and large, high performance generators. In the form of laminated, wound or punched sheets, it is the essential core material of distribution transformers, power transformers and small transformers

Grain-oriented electrical steel usually has a silicon level of 3% of the crystal orientation relative to the sheet. It is used for the cores of power and distribution transformers, cold-rolled grain-oriented steel is often abbreviated to CRGO.

Core laminations are the main part of an electrical transformer, and this attribute to 70% of a transformer cost. These core laminations are required to be cut from special steel called as Cold Rolled Grain Oriented Electrical Steel or popularly known as CRGO. The CRGO is a special quality of steel which have a special grain surface and comes in a thickness of 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm. (generally called M3, M4, M5 & M6). Lower the thickness of material better is the quality of material.

The Quality of CRGO is measured in terms of lower losses of electrical current, which flow in the core. The proper design of core and good quality of core material do a best job in combination. Mainly the core losses are measured in Watts per Kg.

Every type of steel has “grains” which consist of “domains”. These “domains” are nothing but electrical charges oriented in any random direction. Therefore if a transformer were to be made of Mild Steel used as core material, the core loss would be approx. 16 to 17 w/kg at 1.5T/50Hz and the size of the transformer would be approx. 18 to 20 times the size of a transformer manufactured with GO steels

Properties of CRGO Steel

It is a soft magnetic material and has the following properties:

- High magnetic permeability.

- Reduced magnetostriction.

- High resistivity.

- High stacking or laminating factor allows compact core designs.

- Low losses.

Grades of CRGO Steel

- The early grades of steel were known as M7(0.7watts /lb at 1.5T/60Hz) and M6(.6watts/lb at 1.5T/60Hz).

- Similarly, M5 M4 and M3 grades were developed in the late sixties.

- A new material called Hi-B has a remarkable degree of orientation and is 2 - 3 grade better than conventional CRGO steel products.

Types of CRGO:

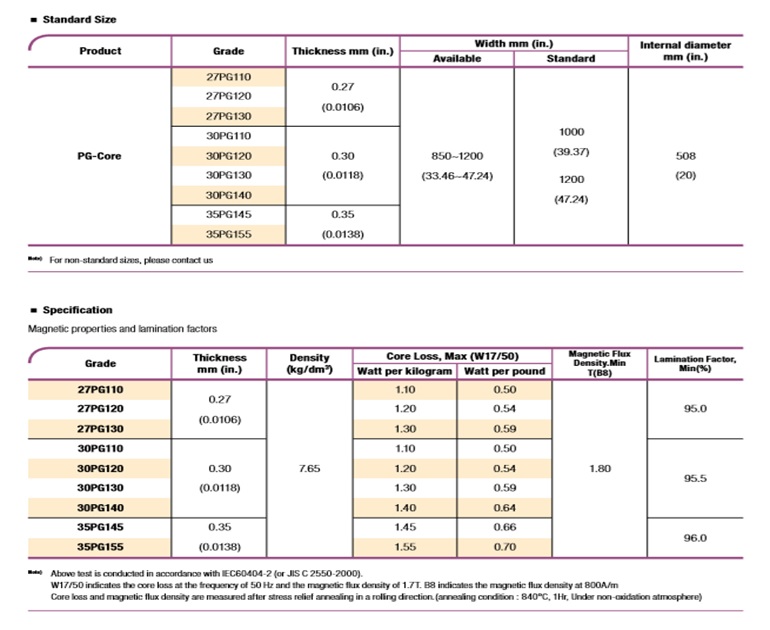

A] PG-Core

The grain structure of PG-core is oriented to the rolling direction. Therefore, this product has excellent magnetic properties in the rolling direction. It is widely used for large or mid/small-size transformers.

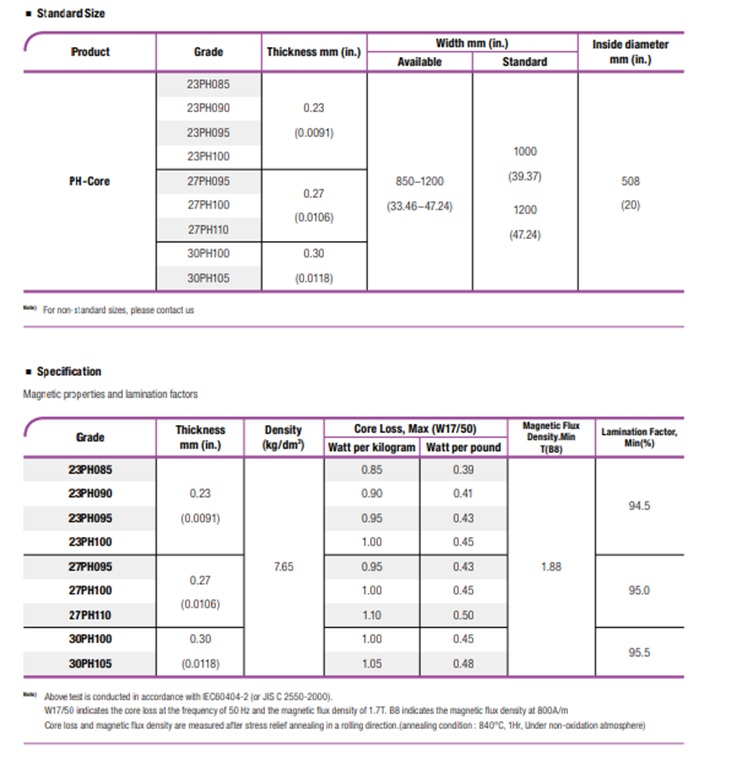

B] PH-Core

The degree of grain-oriented is reinforced in the rolling direction more than PG-Core and therefore features lower core loss and higher magnetic flux density. It is used for iron core of both large and other size power transformers and desirable for high efficiency and miniaturization of machinery

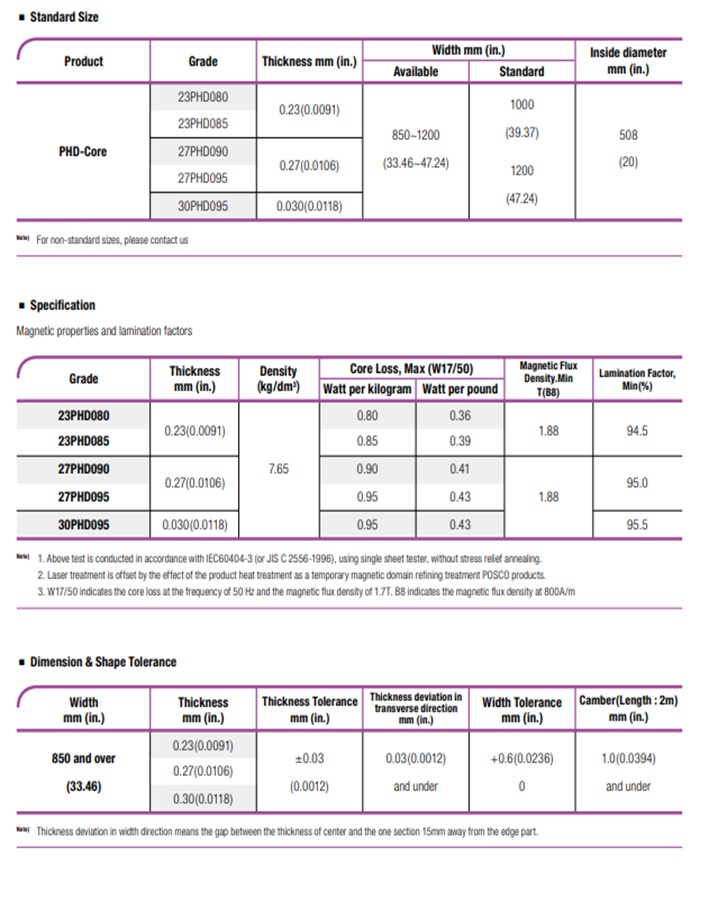

C] PHD-Core

Magnetic domain refined steel is the product that has been specially treated with laser scribing to lower the core loss by 30% from that of CGO steel. Energy efficiency is highered and magnetostriction is lowered, resulting in low noise of this domain refined steel. It is used for not needed. Power transformers that have not been heat treated.