Types of CRNGO

CRNGO: Cold Rolled Non-Oriented Electrical Steel (Non-Oriented Electrical Steel)

The term oriented, when used in conjunction with electrical steels, refers to a crystal structure having magnetic properties that are materially better in a given direction. Some silicon steels are not intentionally oriented and can be called nonoriented steels.

For all practical purposes, Electrical Steels, from grades M-15 to M-47, are nonoriented materials. In other words, their magnetic properties with respect to the direction of rolling are primarily random. In applications such as motor laminations, where flux may flow in any direction with respect to the rolling direction, and in many other applications where cost of producing the part is of paramount importance, the nonoriented grades provide satisfactory performance.

CRNGO steel usually has a silicon level of 2 to 3.5% and have similar magnetic properties in all directions in plan of the sheet. Non-oriented Electrical steel are principally used for motors, generators, alternators, ballasts, small Transformers and a variety of other electromagnetic applications.

Non-oriented electrical steels do not use a secondary recrystallization process to develop their properties, and high temperature annealing is not essential. Therefore, a lower limit on silicon, such as is required for the oriented grades, is not essential.

Microstructure of CRNGO

Non-oriented electrical steel grades contain between 0.5 and 3.25% Si plus up to 0.5% Al, added to increase resistivity and lower the temperature of primary recrystallization. Grain growth is very desirable in the (CRNGO) non-oriented electrical steel grades, but is generally much smaller than for the oriented electrical steel CRGO grades.Processing to hot rolled band is similar to that described for the oriented grade. After surface conditioning, the bands are usually cold rolled directly to final gage, and sold to the transformer manufacturer in one of two conditions fully-processed, or semi processed. After final cold rolling, the strip is annealed, decarburizing it to 0.005% C or lower and developing the grain structure needed for the magnetic properties. Samples are then taken from each coil end, and tested.

Non-oriented steels CRNGO are not as sensitive to strain as the oriented product. Consequently, shearing strains constitute the only strain effects, which should degrade the magnetic quality. Because laminations are generally large, these shearing strains can be tolerated. Most of the fully processed grades are used as stamped laminations in such applications as rotors and stators.

The non-oriented electrical steels (CRNGO) have a random orientation. They are commonly used in large rotating equipment, including motors, power generators, and AC alternators. Fully processed steels are given a “full” strand anneal (to develop the optimum magnetic quality), making them softer and more difficult to punch than semi-processed products. Grades with higher alloy content are harder and thus easier to punch.

| Grade | Processing |

|---|---|

| M-15 | Fully Processed |

| M-19 | Fully Processed |

| M-22 | Fully Processed |

| M-27 | Fully Processed |

| M-36 | Fully Processed |

| M-43 | Fully Processed, Semi-Processed |

| M-45 | Fully Processed |

| M-47 | Fully Processed, Semi-Processed |

Types of CRNGO:

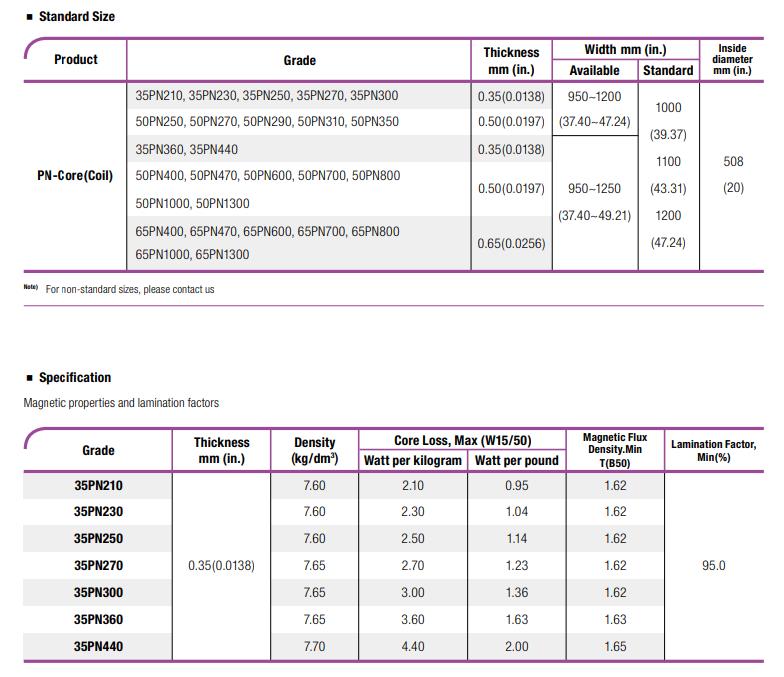

A] PN-Core

Non-oriented electrical steel features homogeneous magnetic properties in all directions. They are widely used as iron core materials in rotating machines ranging from large power generators to tiny precision electric motors. They are also used in the iron core of small power transformers.

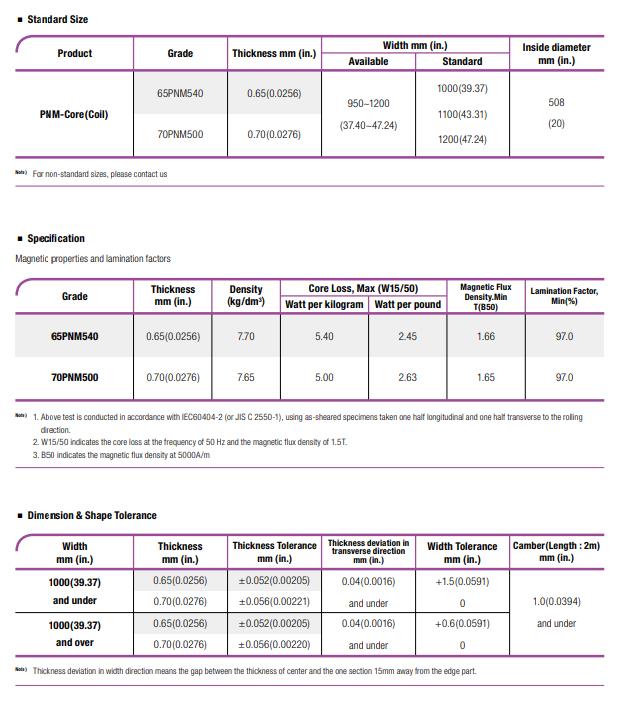

B] PNM-Core

Non-oriented electrical steel features homogeneous magnetic properties in all directions. It is a popular material for magnetic switches as it offers improved wear resistance and low residual magnetism

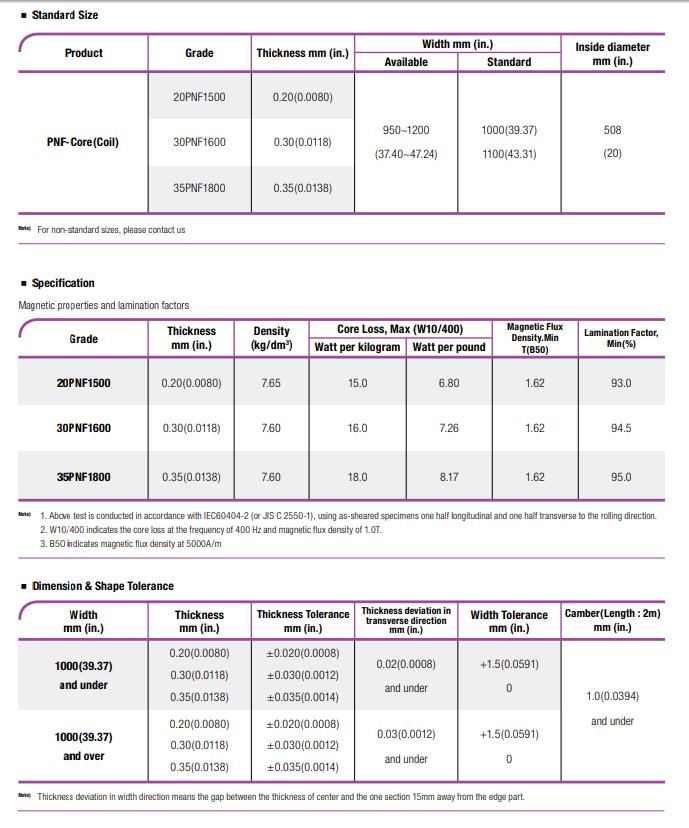

C] PNF-Core

The Eddy current losses increase sharply compared to conventional 0.35mm compared to about 40% of Poles have 0.2mmt products and thinning, The solid core loss characteristics at high frequencies.

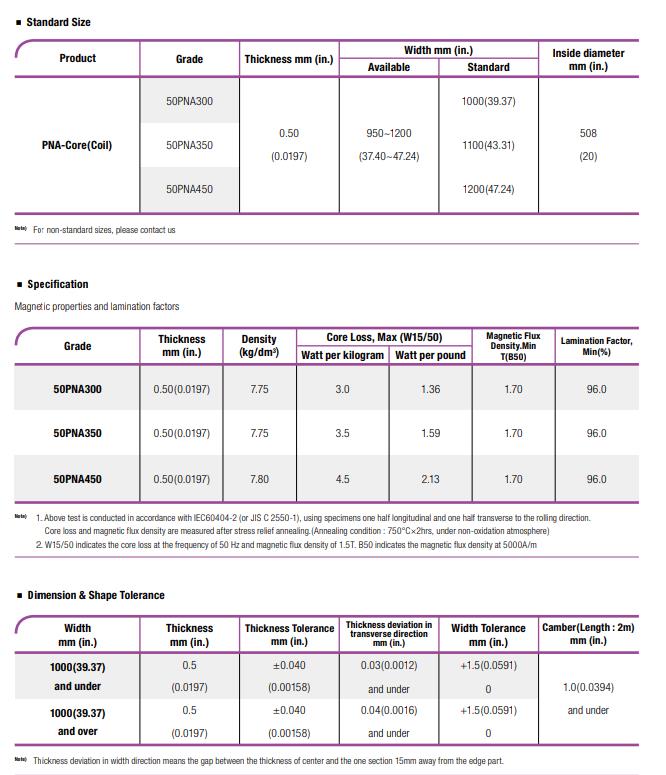

D] PNA-Core

After annealing (SRA, Stress Relief Annealing) material for cost savings for our clients improve competitiveness The product has a low iron loss, flux density, and processing characteristics.

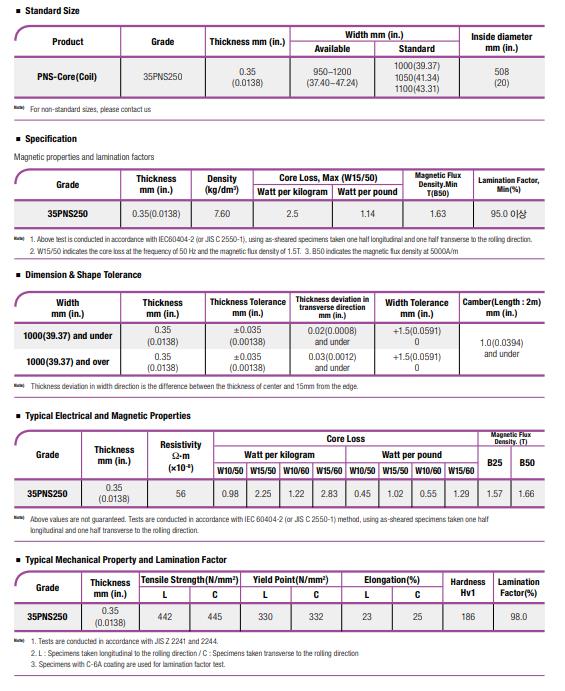

E] PNS-Core

PNS-Core has less strength compared to Hyper grade non-oriented steel of 50PN250. To improve punchability of customer resatiy in increased life cycle of mold.