What is Galfan?

What is Galfan?

One hot-dip coating that was successfully developed is zinc-5% aluminum (Zn-5% Al) alloy-coated steel sheet, the most popular version of which is known throughout the world as GALFAN. It is a registered trademark of the Galfan Technology Center, Inc. (GTC) http://galfan.com/home.html. This website lists all the active producing Galfan® licensees.

The ASTM steel sheet product specification for Zn-5% Al alloy-coated sheet is A875/A875M. The coating is available in two types: Type I alloy coating contains small additions of rare earth mischmetal (Zn-5Al-MM) and is what is used to produce sheet under the trade name Galfan®. Type II contains 0.1% magnesium (Zn-5Al-Mg). Zinc-5% Al alloy-coated sheet is also manufactured and sold under other trade names.

Both Type I and Type II can be used for prepainted sheet as specified in A755/A755M.

Specifications EN 10214 and ISO 14788 are other documents that can be used to specify Zn-5% Al coated sheet.

Manufacture

In the 1970s, research in America, Europe, and Japan experimented with zinc coatings containing up to 15% aluminum. This research found that zinc with 5% Aluminum provided the best corrosion resistance but the problem of small, unwetted bare spots stymied commercialization of the alloy as a coating until further research conducted on the Zn-5% Al system determined that the addition of small amounts of rare earth mischmetal containing cerium and lanthanum improved fluidity, wettability, coating ductility, and inhibited intergranular corrosion. This mischmetal formulation is what later became known as Galfan®.

Composition of the mischmetal-bearing alloy used to produce GALFAN is specified in ASTM B750. The technology used to manufacture this alloy is licensed technology.

Galfan® sheet products are coated on processing lines that are almost identical to those used to produce galvanized sheet. In some cases, production lines that produce Zn-5% Al coatings are dedicated to this product, although most lines that produce GALFAN also produce galvanize through the use of dual, interchangeable coating pots.

Coating Metallurgy and Microstructure

Zinc with 5% aluminum is a eutectic alloy. A eutectic composition is that ratio of elements having the lowest melting temperature, and is located at the intersection of the elements’ liquidus curves in a phase diagram (a representation of what occurs when elements are mixed together). The eutectic is a unique temperature-composition point for two or more elements. Lowering the temperature to just below the eutectic temperature results in a reaction where the all of the liquid mixture freezes to a complete solid at that temperature. In non-eutectic mixtures, freezing occurs over a range of temperatures, and elements can segregate into phases.

Regular zinc galvanizing alloys freeze into a single-phase microstructure. Al-Zn alloys such as Galvalume® form two-phase microstructures in which aluminum phases are surrounded by the lower freezing temperature zinc phase. Galfan®, however, forms a hypoeutectic microstructure in which the high zinc phase and high aluminum phase freeze into very thin, alternating parallel plates called lamellae. Control of the cooling rate is necessary to ensure that the entire microstructure is lamellar.

The intermetallic alloy layer that forms between the Galfan® coating and the steel substrate is a very thin (1 µm) ternary Al-Fe-Zn compound. This layer is thinner than a similar layer that forms on galvanized sheet, and is the reason for the extremely good formability of Galfan®.

Corrosion Resistance

Regular galvanized coatings corrode in the atmosphere by the zinc being continually converted to zinc oxide and zinc carbonate. The lamellar eutectic microstructure of Galfan®, interferes with this mechanism, as corrosion must follow the direction of the thin lamellae. Also, the dense, more passive, aluminum-rich corrosion products that are left behind lower the reactivity of the surface. Naturally, corrosion will be slowest when the lamellae are parallel to the sheet, but even the random orientation that the lamellae usually take greatly reduces the corrosion rate.

The results of field studies have shown that Galfan® has a minimum of two times better outdoor corrosion resistance than conventional galvanize of the same coating weight. This is the case in rural, industrial, and marine environments.

The issue of whether to use galvanize or Galfan® for a particular end use therefore becomes one of overall value versus initial cost. If the objective is to have products last over 2 times longer than those made with galvanize, then the same coating weight as used with galvanize can be specified. If lower initial cost is paramount, then the same service life can be obtained by specifying one-half the normal galvanize coating weight.

Conclusion

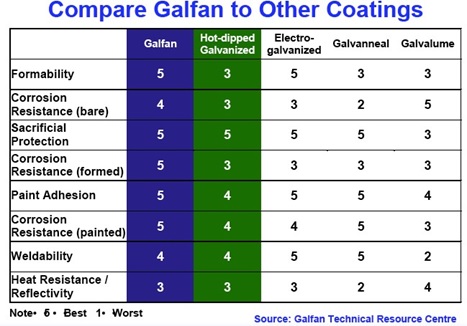

Below figure shows that Galfan® is equal to or better than galvanize in all the important coated sheet attributes.

Zinc-5% aluminum hot-dip coated sheet has corrosion resistance at least twice as good as galvanize. It has been in use for 25 years and has application in many markets, including construction, agriculture, appliance, automotive, highway, and utility.

More information on this product can be found at: http://galfan.com/home.html

- Source: www.galvainfo.com